GARP® increases production by:

GARP® lowers pulling costs by:

GARP® reduces operating costs by:

We design, provide the necessary parts, and will deliver the necessary parts and assemblies with a well diagram showing placement in the well string. We will also provide consultation to ensure it is installed properly and is functioning properly after installation. The operator maintains operation of the well which is no different than the normal operations.

ALL DESIGNS

GARP Bi-Flow Sump Separator

GARP LITE SUMP Advantages

GARP with gas lift – Advantages

Any rod pumped well that has issues with gas separation, solids, reservoir sensitivity or has the pump installed high to the reservoir

The cost to install the equipment depends on numerous factors such as depth, casing size, and existing production equipment and facilities. The down-hole equipment costs for the Bi-Flow Sump Gas Separator Assembly can be as low as $6000 and a GARP® Lite installation can be as low as $15K. Call your GARP Services representative for a quote.

There are four main designs that increase rod pump production:

GARP® Bi-Flow Sump Separator

GARP® Lite

Full GARP® with gas lift assist

Two Step GARP® Lite to Full GARP®

This new technology allows fluids to be pumped down the production tubing with a rod pump installed in a seating nipple. This is accomplished by placing a pressure actuated valve in a mandrel above the seating nipple. Applications include a more efficient paraffin and chemical treating system, and a method to circulate down-hole solids to the surface. We are currently looking for test wells to prove up the technology for no charge. Contact us if you are interested.

This new technology reduces the volume of the casing annular liquids by ~ 2/3 which results in a faster contact of annular gas with the plunger, faster plunger travel times, no stalls, more trips per day and thus higher production per day. It can also allow plunger lift installations on wells that were thought not to be plunger lift candidates. The larger outer diameter tubing is achieved by securing a material to the outside of standard tubulars that is corrosion resistant and can withstand 1000 deg F. We are currently looking for test wells to prove up the technology for no charge for the larger OD material. Contact us if you are interested.

GARP contains two main methods which significantly increases the capacity of down-hole gas separation and also raise liquids from below the pump to above the pump.

Both methods increase the gas separation capacity dramatically over conventional down-hole gas separators by utilizing packer type separation system instead of a conventional tubing anchor/gas anchor system.

Both methods combine a sucker rod pump (or other applicable pump) with a concentric tubing arrangement to allow the pump to be placed in a “pump friendly environment” to keep operating costs low.

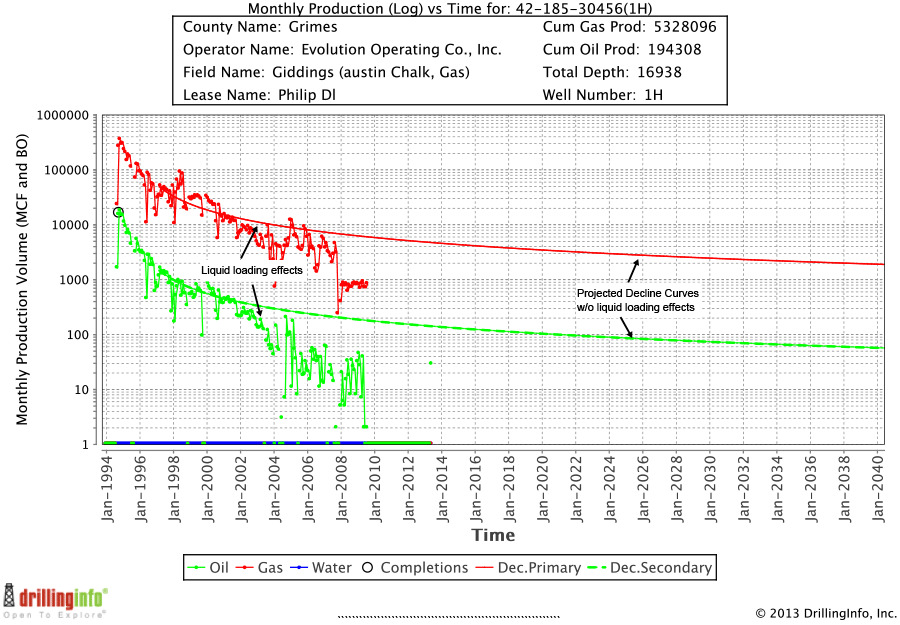

GARP will increase production from the wellbore, but only up to the limit of the down-hole pump. Therefore, the ability to separate out gas from the liquids often is over the capacity of the pump to lift the liquids from the well. Call a GARP Services representative for an analysis of your well. Every well is different. Send us your PI/IPR curve or historic production data (oil, water, gas) for each well and we will analyze the data to determine if GARP can help. We have seen rate increases up to 20 fold and reserve increases over 35% of the cumulative oil and gas produced to date.